Corrugated paper products are functional packaging items made primarily from corrugated cardboard as the core material, processed through specialized manufacturing. Leveraging the advantages of “strong structural adaptability, cost-efficiency, and environmental friendliness,” they have become one of the most widely used products in the global packaging market, covering logistics, product sales, industrial protection, and other scenarios. The following is a detailed description from key dimensions:

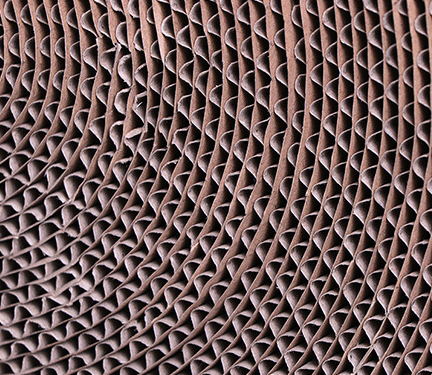

Cushioning and protection: The wavy structure of corrugation creates ‘elastic support,’ allowing the deformation of the corrugation to absorb impact energy under external forces (such as drops or collisions). Meanwhile, the hollow structure isolates external vibrations, effectively protecting internal products (such as glassware or electronic components) from damage.

Load-bearing and compression resistance: The multi-layer composite structure helps distribute pressure, allowing stacked boxes to support the weight of the upper layers without easily deforming or collapsing.

Printing adaptability: The surface of the liner paper is flat and absorbs ink well, allowing for clear color patterns and text printing via flexography, lithography, or digital printing processes, which can both convey product information and enhance brand recognition.

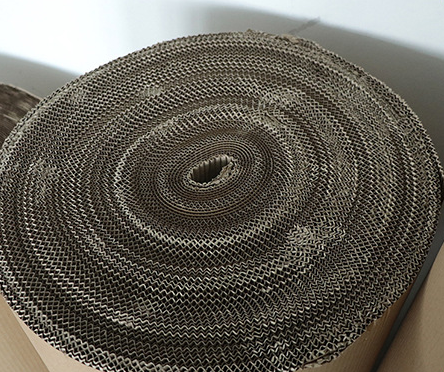

Storage convenience: Unformed corrugated cardboard can be stored in rolls or flat sheets. Folded flat when idle, formed cartons occupy only 1/10 of the space compared to their assembled state, significantly saving storage space and reducing warehousing costs.

Logistics and transportation packaging: This is the most core application area, such as courier boxes (suitable for small e-commerce packages), appliance packaging boxes (double-wall corrugated cartons for refrigerators and washing machines, with internal corrugated partitions for separating accessories), and fresh food transport boxes (surfaces can be coated with PE film or water-resistant agents to prevent moisture and leakage).

Product sales packaging: Used in terminal retail scenarios, such as food boxes (color-printed corrugated boxes for biscuits and pastries, combining protection and aesthetics), toy packaging (windowed corrugated boxes to showcase products while providing strength), and gift packaging (high-end corrugated boxes with foil stamping or lamination, replacing traditional paper boxes and being more environmentally friendly).

Industrial protective packaging: For industrial parts and mechanical components, such as corrugated pallets (replacing wooden pallets, resistant to pests, lightweight, suitable for export), corrugated protective corners (to wrap product edges and prevent collisional wear), and corrugated inserts (filling product gaps and securing placement, such as corrugated inserts for electronic products).

Special scenario packaging: Such as medical supplies packaging (using non-fluorescent, sterile corrugated cardboard to meet medical safety standards), agricultural product packaging (e.g., fruit corrugated boxes with internal partitions to separate individual fruits, reducing compression damage), and eco-friendly returnable boxes (thickened reusable corrugated boxes replacing plastic totes to reduce pollution).

Langfang Haicheng Packaging Co., Ltd.

- Phone: +86 139-13903268466-8466

- Business Type: Manufacturer

- Location: China

- Main Products: Cardboard container

- Total Employees:Less than 100 people

- Year Established:

- Export Markets:

- Total Annual Revenue: