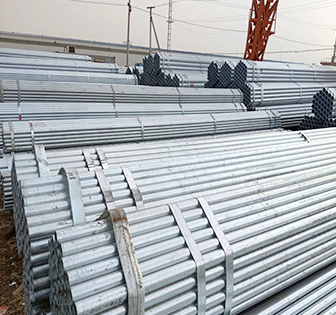

Galvanized conduit, as a crucial cable protection pipe in electrical wiring systems, has become the preferred choice for various construction and industrial projects due to its excellent performance, wide applicability, and outstanding cost-effectiveness.1. Product Structure and MaterialGalvanized conduits are made from high-quality precision high-frequency welded carbon steel pipes, which have good mechanical properties and processing performance. The internal and external surfaces of the steel pipe undergo pretreatment, followed by a hot-dip galvanizing process that ensures the zinc layer tightly adheres to the surface of the pipe, with a typical zinc content of ≥300g/㎡. This process not only grants the conduit excellent rust and corrosion resistance but also significantly enhances its lifespan. Some products undergo fine processing to remove weld spatter and burrs on high-quality galvanized steel pipes, ensuring a smooth inner surface to prevent scratching of wire insulation during threading.2. Product CharacteristicsRust-resistant and durable:The galvanized layer acts as a robust armor, effectively isolating air, moisture, and various corrosive substances from the steel pipe, greatly reducing the risk of rust and corrosion. Whether in a humid indoor environment, such as kitchens and bathrooms, or facing harsh outdoor conditions like wind, rain, and high salinity in coastal areas, galvanized conduits maintain stable performance and are not easily damaged over long-term use, providing reliable protection for cables.Compared to ordinary steel pipes, its corrosion resistance is significantly enhanced, extending its lifespan multiple times under normal usage conditions, reducing replacement and maintenance costs and hassle.Exceptional strength, safety, and reliability:The steel-based structure endows galvanized conduits with high mechanical strength. They can withstand impacts, compression encountered during handling and installation, as well as external forces in the working environment, such as foot traffic or vehicle traffic when laid on the ground, and the weight of cables and the conduit itself when installed in ceilings. They are not easily deformed or broken, creating a solid protective barrier for internal wires and cables, ensuring the safe and stable operation of electrical circuits.Even in special locations like industrial plants with frequent vibrations and mechanical impacts, galvanized conduits can protect cables from damage due to their outstanding strength, maintaining the continuity of power supply.Easy installation and simple maintenance:The product surface is smooth and is equipped with a variety of interface accessories, including straight joints, elbows, junction boxes, etc., to meet the connection needs in different wiring scenarios. During installation, connections can be made using methods like threaded connections, socket joint connections (suitable for small diameters), spigot and socket connections, or clamp connections (suitable for large diameters), which are easy to operate, saving time and effort, effectively improving construction efficiency.Due to the stable nature of the galvanized layer, under normal usage conditions, frequent maintenance is unnecessary; regular simple inspections are enough to ensure it remains in good working condition for a long period, significantly saving on later maintenance costs and manpower investment.