1、 Excellent insulation performance, full energy-saving efficiency

Ultra low heat loss, significantly reducing energy waste

The polyurethane insulation layer adopts high-density foaming technology, with a closed cell rate of over 90% and extremely low thermal conductivity (usually ≤ 0.024W/(m · K)), far superior to traditional insulation materials such as rock wool and glass wool. In centralized heating systems, it can effectively reduce the heat loss of hot water during transportation, making the end user's room temperature more stable, while reducing the energy consumption of heat sources (such as thermal power plants and gas boilers). It is estimated that energy costs can be saved by 20% -30%.

Adapt to a wide temperature environment, suitable for both hot and cold use

Not only suitable for high-temperature hot water transportation (≤ 120 ℃), but also meets the insulation needs of low-temperature fluids (such as chilled water and air conditioning refrigerants). Its performance is stable within the range of -50 ℃ to 130 ℃, avoiding insulation layer aging or failure caused by drastic temperature changes. It is suitable for various scenarios such as heating in northern cold regions and cooling in southern air conditioning.

2、 Integrated structure, dual guarantee of durability and safety

Three layer protection, strong corrosion resistance and impact resistance

The pipe material usually consists of "working steel pipe (conveying medium)+polyurethane insulation layer (insulation)+high-density polyethylene (HDPE) outer protective pipe (protection)":

The working steel pipe can be selected from seamless steel pipe, spiral steel pipe, etc., with compressive strength;

HDPE outer protective pipe is resistant to acid and alkali, UV rays, and soil corrosion, avoiding erosion of the pipeline by underground environments such as damp and saline alkali land;

The overall structure has excellent impact resistance and can withstand the pressure of compaction and underground soil settlement during construction backfilling, with a service life of up to 30-50 years.

Sealed and moisture-proof to prevent "cold bridges" and condensation

The insulation layer is tightly adhered to the working steel pipe and outer protective pipe, and foam sealing technology is used to effectively block the infiltration of external water vapor, avoiding the insulation layer from being affected by moisture and reducing its insulation performance. In low-temperature transportation scenarios (such as air conditioning chilled water), it can prevent condensation on the outer wall of pipelines and reduce the damage of condensed water to surrounding soil or building structures; In high temperature scenarios, avoid the formation of "cold bridges" caused by heat passing through pipe supports and other parts, which can lead to heat loss.

3、 Prefabricated direct burial design, with extremely low construction and maintenance costs

Factory prefabrication, on-site direct burial, construction efficiency increased by 50%+

The insulation layer and outer protective tube are formed in one go in the factory, without the need for on-site winding or wrapping of insulation materials, reducing on-site operation processes. During construction, direct excavation of trenches, laying of pipelines, and backfilling can be carried out, eliminating the complex steps of traditional pipelines such as "welding → rust removal → painting → wrapping insulation layer", greatly shortening the construction period, especially suitable for projects such as urban main roads and underground pipeline networks in residential areas that are sensitive to the construction period.

Buried laying, saving space and not affecting the surface environment

No need to build overhead supports, buried directly underground, does not occupy ground space, does not affect road traffic, green landscape or building layout, especially suitable for urban core areas, residential communities, industrial parks and other land scarce scenarios, reducing interference with the lives or production of surrounding residents.

Easy maintenance and simple troubleshooting

The surface of the outer protective tube is smooth and can be used in conjunction with a leakage alarm line (optional). If the pipeline is damaged or leaked, it can quickly locate the fault point. And due to the strong protective effect of the outer protective tube, frequent maintenance is not required in daily life, only regular inspections are needed, reducing later operation and maintenance costs.

4、 Widely applicable scenarios, outstanding cost-effectiveness

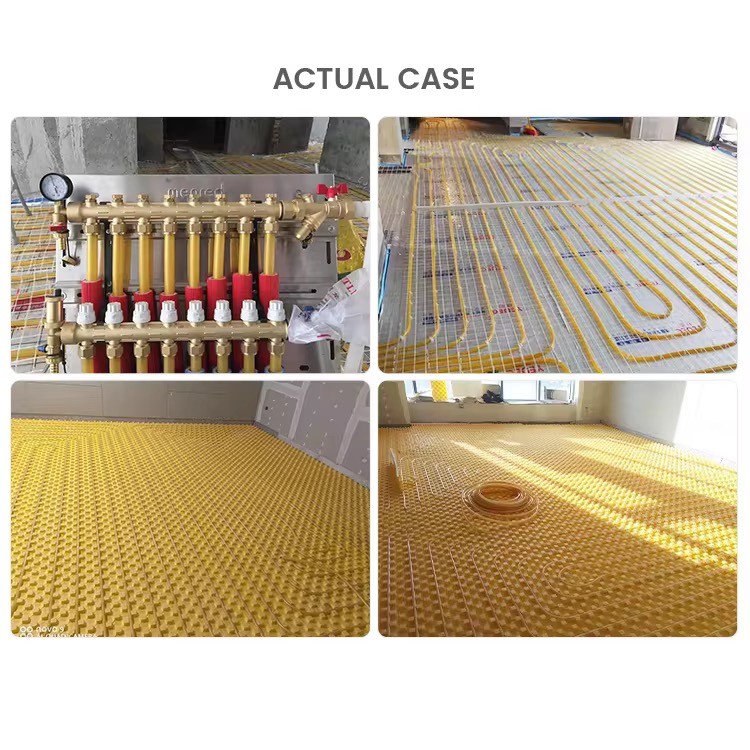

Adapt to fluid transportation in multiple fields

Widely used in:

Central heating system (urban heating network, residential heating branch line);

Industrial pipelines (transportation of cold and hot media in the chemical and pharmaceutical fields);

Central air conditioning system (chilled water, cooling water pipelines);

Pipeline connections for new energy systems such as ground source heat pumps and solar thermal systems.

Significant long-term cost-effectiveness advantage

Although the initial procurement cost is higher than the combination of traditional pipelines and insulation layers, considering its low energy consumption (reducing energy expenditure), long lifespan (reducing replacement frequency), and short construction period (reducing construction costs), the total lifecycle cost can be reduced by more than 40%, especially suitable for large-scale projects or long-term use projects.

5、 Compliant with green and environmental policies, supporting low-carbon development

The insulation layer material polyurethane can be recycled, and the outer protective pipe HDPE is an environmentally friendly material. There is no toxic substance release during production and use, which meets national environmental standards.

Due to significantly reducing energy consumption, decreasing the use of fossil fuels such as coal and natural gas, indirectly reducing carbon emissions, and helping to achieve the "dual carbon" goal, it is an energy-saving pipeline product promoted by the government.

This product is fully customizable

Jinghua Plastics Co., Ltd

- Phone: +86 0316-5118565

- Business Type: Manufacturer

- Location: China

- Main Products: Building drainage pipe fittings, electrical conduits, flame-retardant wire trays, PP-R water supply pipe fittings, PE-RT floor heating pipes, etc

- Total Employees:100-500 people

- Year Established:2010

- Export Markets:Domestic Market,North America,South America,Asia,Europe,Africa,Oceania

- Total Annual Revenue: